NEWS & EVENTS

- Home

- News

- Products Information

- Criteria for Distinguishing Filler Masterbatch and Virgin Resin

Criteria for Distinguishing Filler Masterbatch and Virgin Resin

August 13,2025

When selecting raw materials for plastic production, many people often confuse filler masterbatch with virgin resin, leading to uncontrolled costs and reduced production efficiency. So, what exactly sets these two types of plastics apart? This article by VNapex will guide you through the key criteria for identification, advantages, and disadvantages of each type to help you make informed investment decisions.

Because of its original and pure source, virgin resin possesses ideal chemical and mechanical properties. This is why filler masterbatch and virgin resin are often compared regarding quality and cost in the plastics industry. The main drawback of virgin resin is its high production cost, which requires careful calculation by businesses to avoid impacting profit margins.

Outstanding features of virgin resin:

Normal plastic granules have high purity and do not contain impurities

The main purpose of using filler masterbatch is to help businesses optimize production costs by partially replacing virgin resin while improving certain properties of the final product, such as strength, hardness, heat resistance, and surface gloss.

Filler masterbatch is widely used across industries, including packaging, foam bags, household plastic products, pipes, wire sheathing, construction materials, furniture, and various technical plastic products.

Filler plastic is often used to replace virgin plastic

Visual Inspection

One of the simplest ways to differentiate the two is through visual observation:

For a more accurate differentiation, specialized measurement equipment can check technical parameters:

Chemical Analysis

Chemical analysis offers the most precise identification:

Chemical analysis helps to clearly identify filler plastic and regular plastic

In the future, filler masterbatch is expected to be developed further to improve mechanical and physical properties while being more environmentally friendly. New types of fillers with features like biodegradability and reduced carbon emissions will play an important role in building a sustainable plastics industry.

Plastic filler is the right choice for sustainable trends

Advantages of choosing VNapex filler masterbatch:

APEX with closed production process, ensures finished product quality

What Are Filler Masterbatch and Virgin Resin?

Filler masterbatch and virgin resin are two common materials in the plastics industry, each with distinct characteristics and applications. The following information will help you understand the differences between them:Virgin Resin

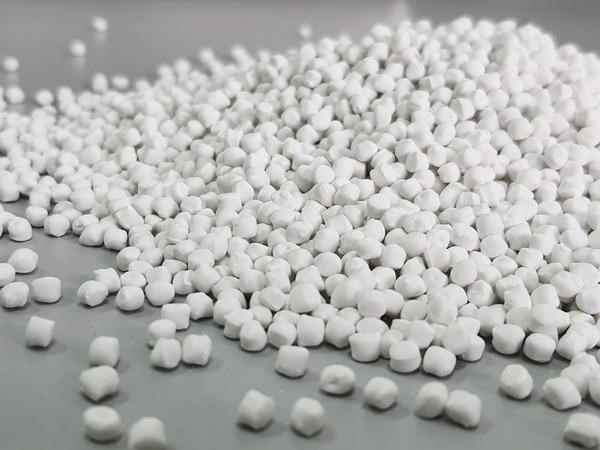

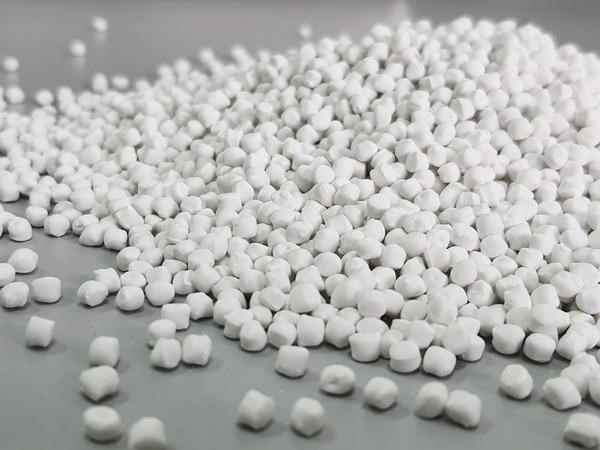

Virgin resin is a type of plastic synthesized directly from crude oil through cracking and polymerization processes. It is the purest form of plastic, never previously used or recycled, and contains no impurities or foreign substances.Because of its original and pure source, virgin resin possesses ideal chemical and mechanical properties. This is why filler masterbatch and virgin resin are often compared regarding quality and cost in the plastics industry. The main drawback of virgin resin is its high production cost, which requires careful calculation by businesses to avoid impacting profit margins.

Outstanding features of virgin resin:

- High purity: Ivory-white color, easy to color accurately, producing products with consistent color and high aesthetics.

- Superior mechanical properties: Strong, impact-resistant, and stable at high temperatures.

- High uniformity: Suitable for products requiring strict technical standards, ensuring consistent quality in mass production.

Normal plastic granules have high purity and do not contain impurities

Filler Masterbatch

Filler masterbatch is a type of plastic pellet produced by mixing mineral powders (most commonly calcium carbonate – CaCO₃) with a base resin and additives. This mixture is processed into small pellets, convenient for use in plastic production processes.The main purpose of using filler masterbatch is to help businesses optimize production costs by partially replacing virgin resin while improving certain properties of the final product, such as strength, hardness, heat resistance, and surface gloss.

Filler masterbatch is widely used across industries, including packaging, foam bags, household plastic products, pipes, wire sheathing, construction materials, furniture, and various technical plastic products.

Filler plastic is often used to replace virgin plastic

Key Criteria for Distinguishing Filler Masterbatch and Virgin Resin

Filler masterbatch and virgin resin are fundamentally different materials in the plastics industry. The table below provides a detailed comparison:| Criteria | Filler Masterbatch | Virgin Resin |

| Origin | Produced by mixing mineral powders (e.g., CaCO₃, talc) with base resin and additives, then formed into pellets. | Synthesized directly from pure crude oil through cracking and polymerization. Never used or recycled. |

| Purity | Moderate, depending on filler quality and blending process. | Very high, impurity-free, with uniform and stable molecular structure. |

| Color & Aesthetics | Often slightly opaque, limited in producing bright or transparent products. | Ivory-white, easy to color accurately, smooth and glossy surface, ensuring high aesthetics. |

| Mechanical Properties | Good if used in correct proportions; can maintain or enhance hardness and mechanical stability. | Excellent, with high strength, toughness, heat and impact resistance, suitable for high-tech products. |

| Processability | Requires careful selection of filler type and strict ratio control. | Easy to process, compatible with most industrial machinery, minimal production issues. |

| Cost | 10–50% lower than virgin resin; stable and controllable. | Significantly higher, heavily dependent on crude oil prices and global market fluctuations. |

| Applications | Common products like packaging, foam bags, household plastics, pipes, disposable items, etc. | High-standard products such as medical devices, food packaging, electronics components, high-tech industrial products. |

| Purpose | Focused on optimizing production costs, increasing output, and maintaining adequate quality for mass-market demand. | Ensures absolute quality, serving premium product segments and markets with strict requirements. |

Methods to Distinguish Virgin Resin and Filler Masterbatch

In plastic production, distinguishing between filler masterbatch and virgin resin is essential, as each type has unique properties suited for different applications and market segments.Visual Inspection

One of the simplest ways to differentiate the two is through visual observation:

- Virgin resin pellets are uniform, bright white, and glossy, indicating high purity.

- Filler masterbatch may show different colors due to mineral fillers like CaCO₃ or talc, and its pellet size is generally smaller than virgin resin.

For a more accurate differentiation, specialized measurement equipment can check technical parameters:

| Property | Virgin Resin | Filler Masterbatch |

| Melting Temperature | High | Low |

| Hardness | High | Low |

| Strength | High | Low |

Chemical analysis offers the most precise identification:

- Virgin resin contains only pure plastic with no fillers or impurities.

- Filler masterbatch is a mixture of base resin and fillers such as mineral powders or clays.

Chemical analysis is commonly used in laboratories, especially when verifying material quality for high-standard products

Chemical analysis helps to clearly identify filler plastic and regular plastic

Which Choice Aligns with Sustainable Development?

With the trend toward sustainability, the choice between virgin resin and filler masterbatch becomes increasingly critical. Virgin resin consumes significant non-renewable resources, is difficult to decompose, and poses environmental pressures (soil, water, and air pollution). In contrast, filler masterbatch reduces production costs but may release microplastics if not handled properly.In the future, filler masterbatch is expected to be developed further to improve mechanical and physical properties while being more environmentally friendly. New types of fillers with features like biodegradability and reduced carbon emissions will play an important role in building a sustainable plastics industry.

Plastic filler is the right choice for sustainable trends

APEX-VN Provides the Best Filler Masterbatch Solutions for Businesses

If your business struggles to find a reliable supplier of quality filler masterbatch, VNapex is the ideal choice. Currently, VNapex is a leading global manufacturer with over 50 years of experience serving international clients.Advantages of choosing VNapex filler masterbatch:

- Cost optimization: Smart formulations allow partial replacement of virgin resin with CaCO₃, reducing production costs while maintaining product quality.

- Enhanced product performance: Filler masterbatch improves hardness, impact resistance, scratch resistance, and heat resistance, crucial for durable and stable products.

- Improved processing stability: Reduces technical issues like warping, cracking, and shrinkage, ensuring consistent quality in large-scale production.

- Better surface quality and printability: Produces smooth, glossy surfaces with minimal shrinkage, enabling sharp printed details and high aesthetics.

APEX with closed production process, ensures finished product quality

Distinguishing filler masterbatch and virgin resin is crucial for controlling costs and ensuring product quality. Depending on your usage needs and market segment, businesses must carefully select the most suitable material. We hope this article provides useful insights if you have further questions about ordering processes or prices, don’t hesitate to contact VNapex today!