NEWS & EVENTS

- Home

- News

- Products Information

- Comparison of Rigid PVC and Flexible PVC

Comparison of Rigid PVC and Flexible PVC

August 13,2025

Among plastic materials, rigid PVC is often chosen for applications requiring high durability, strong load-bearing capacity, and excellent weather resistance. However, flexible PVC also has its own advantages in projects that demand flexibility and ease of bending. Understanding the differences between these two types helps users select the most appropriate material, thereby optimizing both performance and investment costs for each project.

Technical characteristics of rigid PVC:

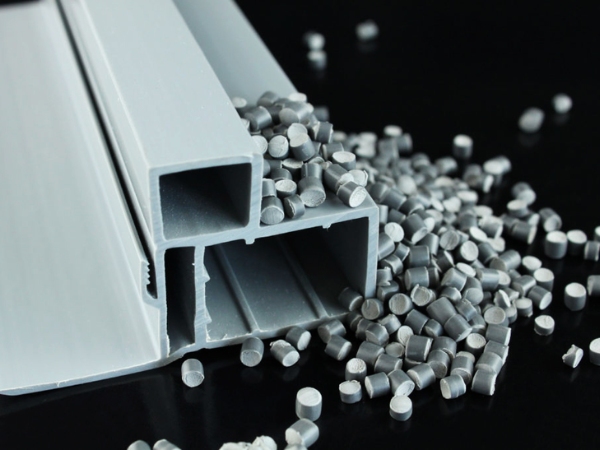

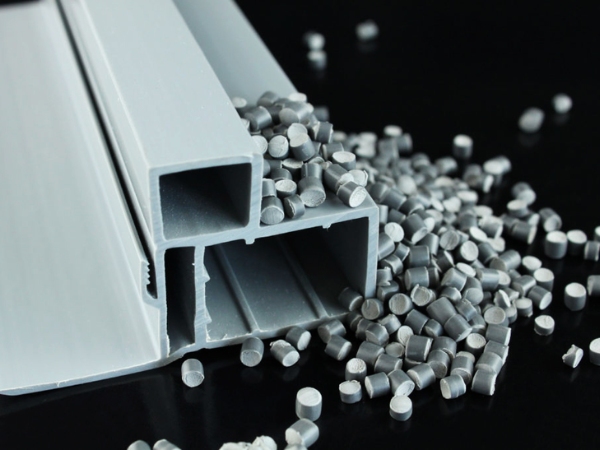

Rigid PVC, also known as uPVC

What is rigid PVC?

Rigid PVC, also known as uPVC (Unplasticized Polyvinyl Chloride), is a type of PVC that contains no or only a very small amount of plasticizers (less than 5%). Unlike flexible PVC, uPVC is highly rigid and maintains its mechanical properties well under pressure or harsh environmental conditions.Technical characteristics of rigid PVC:

- Composition: PVC powder, heat stabilizers, lubricants, and other additives, with virtually no plasticizers.

- Mechanical properties: Hard, durable, strong load-bearing capacity, does not deform under stress.

- Environmental durability: Effectively resistant to UV radiation and corrosive chemicals.

Rigid PVC, also known as uPVC

Thanks to its stable technical properties and low production cost, uPVC is widely used in various industrial fields such as water pipes, oil pipelines, ventilation equipment, wall panels, partitions, and technical products in the construction and industrial sectors.

Both rigid and flexible PVC are synthesized from Polyvinyl Chloride

Typical applications for rigid PVC include:

Application of rigid PVC in industrial piping systems

Common applications include:

Flexible PVC is commonly used to insulate cables and electrical wires

Comparison of rigid PVC and flexible PVC

PVC is one of the most common plastics today, divided into two main types: rigid PVC and flexible PVC. Each type has its own characteristics, suitable for different applications in industry and daily life, specifically:Similarities

Although they differ in mechanical properties due to differences in plasticizer content, rigid PVC (uPVC) and flexible PVC still share many common features regarding origin, recyclability, and technical performance. The main similarities include:- Origin: Both types are synthesized from Polyvinyl Chloride, a thermoplastic polymer. The product’s hardness or flexibility depends on whether plasticizers are added during production.

- Recyclability: Both types of PVC can be collected and recycled; however, processing flexible PVC is usually more complex due to its higher additive content.

- Technical properties: Both rigid and flexible PVC are waterproof, electrically insulating, and chemically resistant, making them suitable for technical applications such as piping, insulation layers, and construction materials. However, in terms of thermal and mechanical strength, PVC does not reach the level of polycarbonate (PC).

- Workability: PVC, whether rigid or flexible, can be processed through various methods such as extrusion, injection molding, calendering, or casting.

Both rigid and flexible PVC are synthesized from Polyvinyl Chloride

Differences

The primary differences between rigid and flexible PVC stem from the use of plasticizers during production. The distinctions below help clarify the properties and suitable applications of each type.| Criteria | Rigid PVC (uPVC) | Flexible PVC |

| Material hardness | High, cannot be bent by hand | Soft and flexible, can be bent easily |

| Elasticity | Low | High |

| Plasticizer content | None or very low (<5%) | High, directly affecting softness |

| Common applications | Water pipes, window frames, panels, construction accessories | Electrical cables, films, medical tubing, flexible hoses |

| Tensile strength | Higher, stable under load | Lower, suitable for flexible applications |

| Impact resistance | Lower, brittle in some conditions | Higher, better impact resistance |

| Density | Higher | Lower |

Which should you choose: rigid PVC or flexible PVC?

The choice between rigid PVC (uPVC) and flexible PVC depends on the technical requirements of each specific application. Each type has its own advantages, suitable for different operating conditions.When to choose rigid PVC?

Rigid PVC, often called uPVC (unplasticized PVC), contains no plasticizers, giving it high rigidity and mechanical strength. This type of plastic is suitable for applications that require strong load-bearing capacity, shape stability, and resistance to weather and chemicals.Typical applications for rigid PVC include:

- Water supply and drainage pipes: Used in residential and industrial water systems due to high pressure resistance and long-term durability.

- Outdoor window frames, doors, and partitions: UV and weather resistance help maintain color and shape over time.

- Technical systems and electrical boxes: Applied in junction boxes, low-pressure piping, or mechanical components due to stability and resistance to deformation.

Application of rigid PVC in industrial piping systems

Advantages of rigid PVC:

- High load-bearing and impact resistance.

- Shape stability, minimal expansion or contraction with temperature changes.

- Resistant to chemicals and UV exposure.

- Difficult to bend or shape into complex forms.

- Requires special processing for drilling, cutting, or welding.

When to choose flexible PVC?

Flexible PVC contains plasticizers, making the material flexible, easy to bend, and capable of deforming without breaking. This type of plastic is suitable for applications that require coating, covering, or forming complex shapes.Common applications include:

- Waterproof coatings: Floors, roofs, or constructions that need moisture and water resistance.

- Cable and wire insulation: Flexible PVC provides good insulation, durability, and flexibility, suitable for electrical wiring, telecom cables, or medical devices.

- Consumer products: Plastic bags, packaging, plastic curtains, films, and flexible tubing for industrial or household devices.

Flexible PVC is commonly used to insulate cables and electrical wires

Advantages of flexible PVC:

Our PVC resin can be customized in color according to specific requirements, making it suitable for various applications. In addition to standard grades, VNapex also supports customers in developing specialized PVC compounds with enhanced technical features, such as improved impact resistance, durability under harsh weather conditions, or performance under specific operational requirements.

Notably, our rigid PVC compounds for extrusion are designed to ensure stable processing performance and easy shaping. These materials not only deliver excellent mechanical properties but are also environmentally friendly, meeting diverse technical requirements in the industrial extrusion plastics sector.

Choosing between rigid and flexible PVC should be based on the technical requirements of each project or product. Rigid PVC is the optimal solution for applications requiring high strength, shape stability, and superior environmental resistance, while flexible PVC is more suitable for applications needing flexibility, easy bending, or rapid installation. If you are looking for a reliable source of high-quality PVC resin, contact VNapex today - a trusted supplier supporting businesses with every technical plastics solution.

- Flexible and easy to bend, ideal for coating and covering applications.

- Good waterproofing, suitable for materials in contact with water.

- Easy to shape and manufacture small or detailed products.

- Lower mechanical strength compared to rigid PVC; prone to scratches or tearing under high stress.

- Poor heat resistance; can deform under prolonged exposure to high temperatures.

VNapex provides high-quality PVC resin

VNapex specializes in supplying high-quality PVC resin that meets strict safety and environmental protection standards. All products are manufactured from environmentally friendly materials and fully comply with current regulations such as ROHS 2.0 and REACH.Our PVC resin can be customized in color according to specific requirements, making it suitable for various applications. In addition to standard grades, VNapex also supports customers in developing specialized PVC compounds with enhanced technical features, such as improved impact resistance, durability under harsh weather conditions, or performance under specific operational requirements.

Notably, our rigid PVC compounds for extrusion are designed to ensure stable processing performance and easy shaping. These materials not only deliver excellent mechanical properties but are also environmentally friendly, meeting diverse technical requirements in the industrial extrusion plastics sector.

Choosing between rigid and flexible PVC should be based on the technical requirements of each project or product. Rigid PVC is the optimal solution for applications requiring high strength, shape stability, and superior environmental resistance, while flexible PVC is more suitable for applications needing flexibility, easy bending, or rapid installation. If you are looking for a reliable source of high-quality PVC resin, contact VNapex today - a trusted supplier supporting businesses with every technical plastics solution.