NEWS & EVENTS

- Home

- News

- Products Information

- Common types of plastic resins in the industry

Common types of plastic resins in the industry

August 13,2025

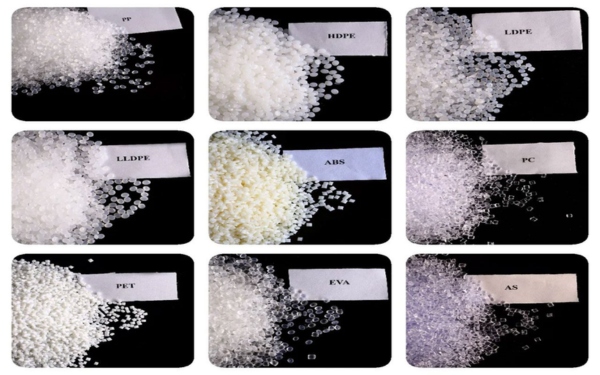

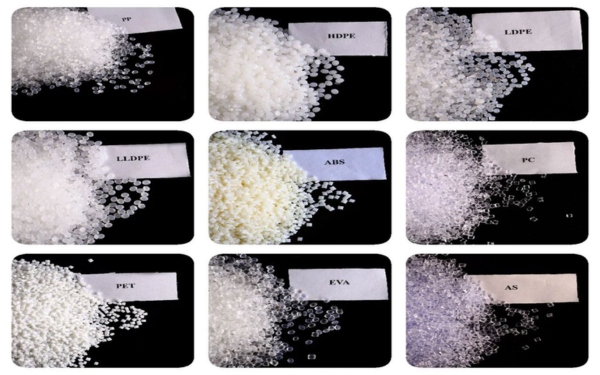

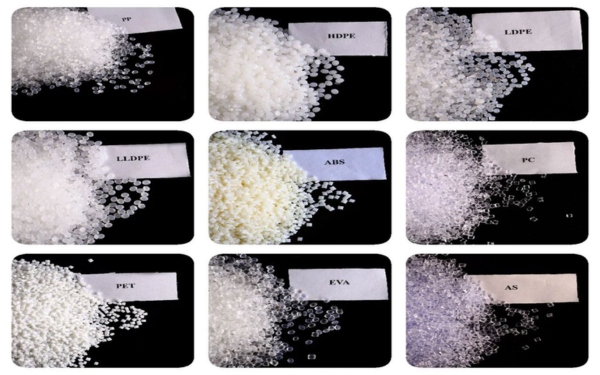

Plastic resins are indispensable raw materials in the plastics manufacturing industry, contributing to the creation of countless products that serve daily life. So, what are the most common types of plastic resins today? How are they applied? Let’s explore in detail with VNapex in the following article!

Common types of plastic resins in industry

There are various types of plastic resins that are widely applied in both daily life and industry - from common products like bottles, bags, and household appliances to high-tech components in the automotive, electronics, and medical fields. Each type of resin has unique characteristics and properties depending on its polymer composition and intended application.

Key features: flexibility, high elasticity, durability, and minimal warping.

Common types of plastic resins in this category include PP, PE, ABS, PS (GPPS/HIPS), PA, PC, POM, PMMA, and more.

Virgin resin is produced directly from petroleum

Although recycled resin is less uniform and may contain impurities, it is more cost-effective and suitable for applications that do not require high technical performance.

Recycled resin is produced from post-consumer plastic products

Bioplastic resin is produced from natural raw materials

Applications: Used in technical components such as electronic device housings (blender, juicer cases), electrical parts (switchboards, sockets), helmets, automotive and motorcycle parts, toys, containers, and many consumer products.

ABS plastic surfaces are easy to process and provide effective electrical insulation

Applications: PP is one of the widely used types of plastic resins, applied in packaging, woven sacks, fertilizer and animal feed bags, plastic containers, cups, bottle caps, automotive parts, waterproof membranes, nonwoven fabrics, plastic boards, and plastic pipes.

Polypropylene is a polymer with good load-bearing capacity and effective moisture resistance

Applications: Used in plastic packaging, shopping bags, food wraps, cable insulation, crates, trays, plastic bottles, caps, and labeling films.

Polyethylene is one of the most commonly used plastics today

Applications: PET is one of the commonly used types of plastic resins, extensively applied in beverage bottles, food packaging, thermoformed containers, trays, textile fibers (clothing, carpets), PET films, and straws.

PET is widely used in the production of beverage bottles

GPPS is suitable for producing disposable food containers

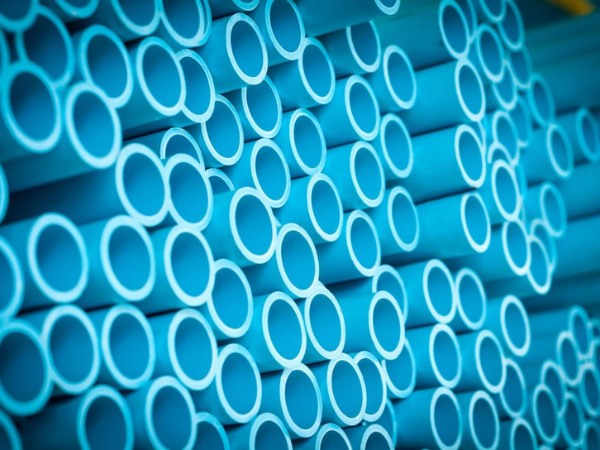

Applications: Used in water supply and drainage pipes, electrical conduits, plastic jerrycans, chemical containers, bottle caps, agricultural films, and geotextile liners.

HDPE is commonly used in the production of water supply and drainage pipes

Applications: Used in thermoformed trays, TV housings, appliance casings, food containers, disposable dishes, electronic components, and decorative interior parts.

HIPS is used to manufacture food containers

Applications: LDPE is one of the widely used types of plastic resins, applied in plastic bags, shrink films, food wraps, cable insulation, container liners, fish tanks, knife handles, plastic roofing, and agricultural films.

LDPE is widely applied in the production of plastic bags

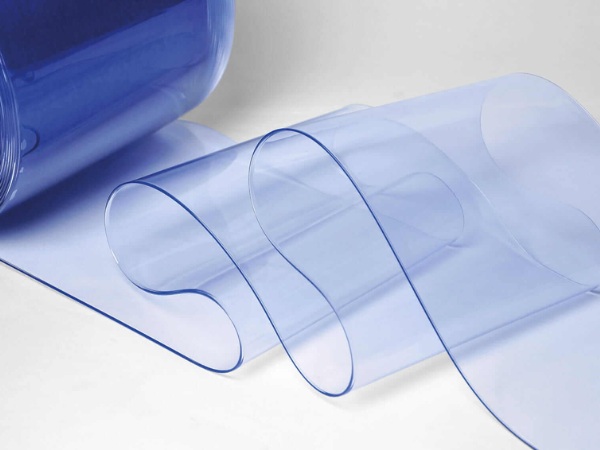

In practice, PVC compounds are often used - PVC resin pre-blended with necessary additives such as heat stabilizers, lubricants, plasticizers, and CaCO₃ fillers - enhancing stability, processability, and suitability for specific applications like injection molding, extrusion, and blow molding.

PVC is a synthetic plastic produced from the polymerization of vinyl chloride

Common types of plastic resins in industry

Introduction to plastic resins

Plastic resin is a granular material, usually white or transparent, used as the primary raw material for producing plastic products. During production, base resins are blended with other components such as color masterbatch, fillers (like CaCO₃ powder), and specialized additives to achieve desired colors, mechanical properties, or technical functions.There are various types of plastic resins that are widely applied in both daily life and industry - from common products like bottles, bags, and household appliances to high-tech components in the automotive, electronics, and medical fields. Each type of resin has unique characteristics and properties depending on its polymer composition and intended application.

What types of plastic resins are on the market?

Currently, the types of plastic resins available on the market are categorized based on origin and material properties into three main groups: virgin resins, recycled resins, and bioplastic resins.Virgin resins

Virgin resin is produced directly from petroleum, unused, and free from impurities. Depending on the polymer type, virgin resins are usually opaque white or transparent and can be mixed with color masterbatch or additives to create desired colors and functionalities.Key features: flexibility, high elasticity, durability, and minimal warping.

Common types of plastic resins in this category include PP, PE, ABS, PS (GPPS/HIPS), PA, PC, POM, PMMA, and more.

Virgin resin is produced directly from petroleum

Recycled resins

Recycled resin is produced from post-consumer plastic products such as bottles, household items, or machinery components. Through processes like sorting, crushing, washing, drying, and melting, recycled plastic is transformed into pellets or fibers. Since it originates from virgin plastics, recycled resins are classified into categories such as recycled PP, recycled PE, recycled ABS, etc.Although recycled resin is less uniform and may contain impurities, it is more cost-effective and suitable for applications that do not require high technical performance.

Recycled resin is produced from post-consumer plastic products

Bioplastic resins

Bioplastic resins are derived from natural raw materials such as corn starch, sugarcane, cellulose, or proteins. Some bioplastics are biodegradable, helping reduce environmental pollution. The most common types today include PLA, PHA, and TPS (thermoplastic starch).

Bioplastic resin is produced from natural raw materials

Common industrial plastic resins and their applications

Each type of plastic resin has its own mechanical, thermal, and chemical properties, meeting different technical and environmental requirements. Below is an overview of popular industrial types of plastic resins and their real-world applications.ABS resin

ABS is an engineering polymer composed of three main monomers: acrylonitrile, butadiene, and styrene. It is known for its high rigidity, excellent impact resistance, and toughness compared to other common plastics. ABS surfaces finish well, are easy to process and mold, and work with various methods such as injection molding and extrusion. ABS is also mildly chemical-resistant and a good electrical insulator.Applications: Used in technical components such as electronic device housings (blender, juicer cases), electrical parts (switchboards, sockets), helmets, automotive and motorcycle parts, toys, containers, and many consumer products.

ABS plastic surfaces are easy to process and provide effective electrical insulation

PP resin

Polypropylene is a semi-crystalline polymer with high mechanical strength, good load-bearing capacity, and effective moisture resistance. It withstands high temperatures (up to 100°C), is non-toxic, odorless, and food-safe. PP also features excellent tensile strength, fold endurance, and easy processability.Applications: PP is one of the widely used types of plastic resins, applied in packaging, woven sacks, fertilizer and animal feed bags, plastic containers, cups, bottle caps, automotive parts, waterproof membranes, nonwoven fabrics, plastic boards, and plastic pipes.

Polypropylene is a polymer with good load-bearing capacity and effective moisture resistance

PE resin

Polyethylene is one of the most widely used plastics today, known for being lightweight, flexible, chemical-resistant, and waterproof. Depending on crystallinity and molecular density, PE is classified into HDPE, LDPE, and LLDPE. Virgin PE is typically opaque white or transparent and can be easily colored as needed.Applications: Used in plastic packaging, shopping bags, food wraps, cable insulation, crates, trays, plastic bottles, caps, and labeling films.

Polyethylene is one of the most commonly used plastics today

PET resin

PET is a thermoplastic polyester formed through the polymerization of terephthalic acid and ethylene glycol. It has excellent mechanical strength, impact resistance, wear resistance, solvent resistance, and can withstand a wide temperature range from -90°C to 200°C. PET is highly transparent, glossy, and has strong tensile strength.Applications: PET is one of the commonly used types of plastic resins, extensively applied in beverage bottles, food packaging, thermoformed containers, trays, textile fibers (clothing, carpets), PET films, and straws.

PET is widely used in the production of beverage bottles

GPPS resin

GPPS is a form of polystyrene commonly used where high impact resistance is not required. It is transparent, rigid, lightweight, colorless, easy to color, and easy to process via molding or thermoforming. However, it is brittle and prone to cracking under mechanical stress or high temperatures.

Applications: Disposable food containers, CD/DVD cases, toys, lightweight insulating materials, plastic trays, and office supplies

GPPS is suitable for producing disposable food containers

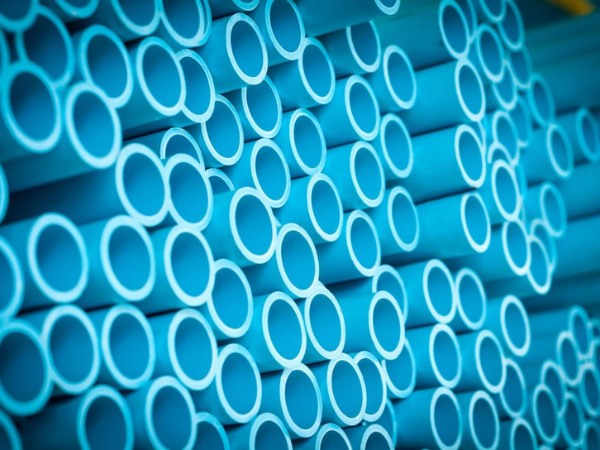

HDPE resin

HDPE is a high-density polyethylene offering superior rigidity and mechanical strength compared to LDPE. It is waterproof, resistant to strong chemicals (acids, alkalis, salts), UV rays, and harsh weather. HDPE maintains its physical properties over long periods and is slow to degrade.Applications: Used in water supply and drainage pipes, electrical conduits, plastic jerrycans, chemical containers, bottle caps, agricultural films, and geotextile liners.

HDPE is commonly used in the production of water supply and drainage pipes

HIPS resin

HIPS is an improved form of polystyrene with enhanced impact resistance. It is opaque white, moderately rigid, and easy to process through molding, sheet extrusion, or thermoforming. HIPS is crack-resistant, does not support microbial growth, and is food-contact safe.Applications: Used in thermoformed trays, TV housings, appliance casings, food containers, disposable dishes, electronic components, and decorative interior parts.

HIPS is used to manufacture food containers

LDPE resin

LDPE is a low-density polyethylene characterized by softness, flexibility, impact resistance, and excellent electrical and thermal insulation. It resists moisture and is unaffected by acids, alkalis, and mild solvents. However, LDPE has lower tensile strength and rigidity compared to HDPE.Applications: LDPE is one of the widely used types of plastic resins, applied in plastic bags, shrink films, food wraps, cable insulation, container liners, fish tanks, knife handles, plastic roofing, and agricultural films.

LDPE is widely applied in the production of plastic bags

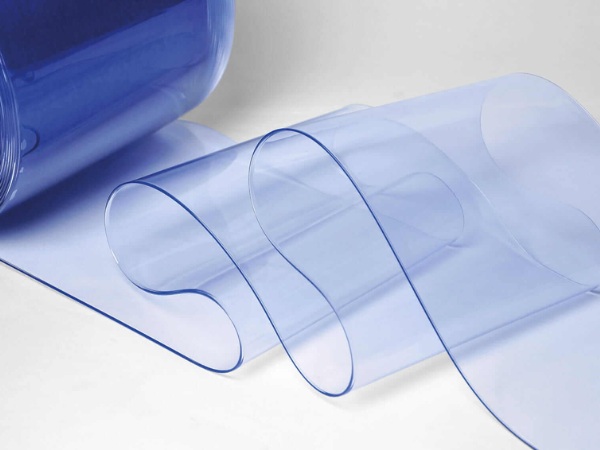

PVC resin

PVC is a synthetic resin produced through the polymerization of vinyl chloride. It features flame resistance, good electrical insulation, weather resistance, chemical resistance, and high mechanical strength. In its pure form, PVC is hard and brittle, but plasticizers can be added to produce flexible PVC.In practice, PVC compounds are often used - PVC resin pre-blended with necessary additives such as heat stabilizers, lubricants, plasticizers, and CaCO₃ fillers - enhancing stability, processability, and suitability for specific applications like injection molding, extrusion, and blow molding.

PVC is a synthetic plastic produced from the polymerization of vinyl chloride

Applications: Water pipes, cable insulation, electrical tapes, roofing sheets, partitions, disposable medical devices, films, plastic cards, synthetic leather furniture, and more.

VNapex - Trusted supplier of high-quality PVC resins

VNapex takes pride in being one of the leading suppliers of high-quality PVC resins for various industries. With many years of experience in plastic raw materials, we are committed to delivering optimal solutions in terms of products, quality, and pricing.- Quality assurance: All VNapex products undergo strict quality control before reaching customers. We guarantee high purity, excellent dispersibility, and compatibility with multiple plastic processing methods such as injection molding, film blowing, and pipe extrusion.

- Professional service: Our technical team is dedicated to assisting clients in selecting the most suitable resin type for their specific applications and production processes, helping reduce costs and maximize efficiency.

- Competitive pricing: At VNapex, we understand that input costs are critical in industrial production. Therefore, we strive to offer the most reasonable prices along with consistent quality and attentive after-sales service.