- Home

- News

- Products Information

- How is extrusion technology applied in plastic manufacturing?

How is extrusion technology applied in plastic manufacturing?

What is plastic extrusion?

Plastic extrusion is a common thermal processing method in the plastics industry. In this process, plastic material - usually in pellet form -is fed into an extruder, melted in a heated barrel, and then continuously pushed through a shaping die to create products with a constant cross-section.Extrusion technology is particularly suitable for manufacturing long products such as pipes, films, profiles, or sheets. Its advantages include high productivity, low tooling costs, and the ability to form large profiles with stable wall thickness - something many other technologies struggle to achieve.

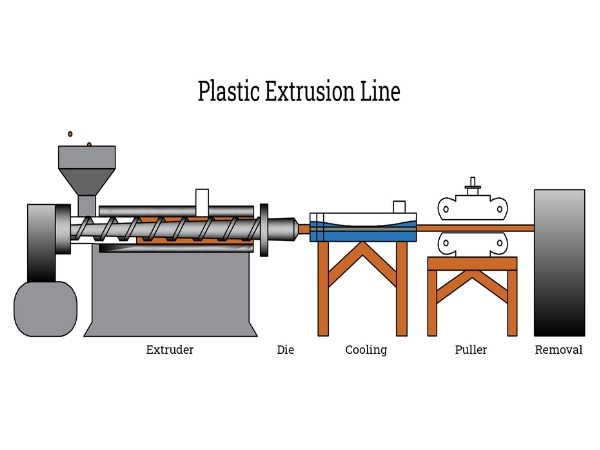

The plastic extrusion process: From raw material to finished product

The plastic extrusion process is a continuous sequence of operations, starting from feeding raw materials to obtaining the shaped final product. Each step is strictly controlled in terms of temperature, pressure, and speed to ensure consistent quality and dimensional stability.Key steps in the plastic extrusion process include:

- Step 1 - Feeding: Plastic pellets are loaded into the feed hopper, from which the material moves into the barrel containing the screw.

- Step 2 - Heating: The material is heated through multiple heating zones along the barrel, allowing the plastic to melt.

- Step 3 - Mixing and conveying: The rotating screw continuously mixes the molten plastic and pushes it toward the die head.

- Step 4 - Filtering and pressurizing: Before entering the die, the plastic passes through a breaker plate to remove impurities, stabilize the flow, and build up necessary pressure.

- Step 5 - Shaping: The molten plastic is forced through a die, which defines the desired cross-section of the product.

- Step 6 - Cooling and finishing: After leaving the die, the product is quickly cooled using a water bath or cooling rolls to lock in its shape. Finally, the product is cut to the required length or wound into rolls in the case of films.

Diagram illustrating the plastic extrusion process

Common plastic extrusion technologies and real-world applications

Plastic extrusion has evolved into various methods to meet specific technical and application requirements in production. Below are the most widely used extrusion technologies and their practical applications.Blown film extrusion

Blown film extrusion is a method of producing thin plastic films by melting plastic pellets, then extruding them through a circular die to form a semi-solid tube. This tube is inflated with air pressure until it reaches the required size and thickness. It is commonly used to produce food packaging bags, shopping bags, agricultural covers, and thin packaging films.

Blown film extrusion technology is applied in food bag production

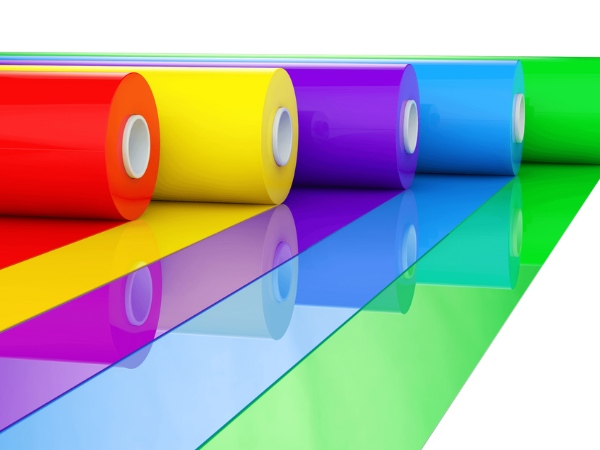

Sheet/Film extrusion

Unlike blown film extrusion, sheet/film extrusion uses a flat die to create a plastic sheet, which is then pulled and cooled through a calendering system. This method is suitable for products requiring greater thickness, such as food containers, thermoformed packaging, and technical plastic sheets.

Sheet/film extrusion is suitable for products requiring greater thickness

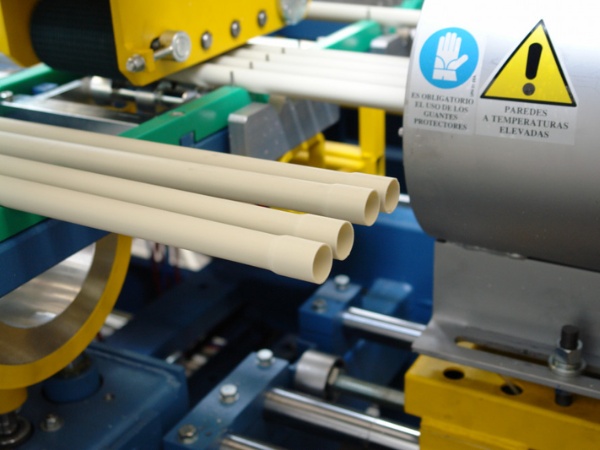

Pipe extrusion

Pipe extrusion is used to manufacture plastic pipes with continuous diameter and length. The molten plastic is shaped through a hollow circular die, while a mandrel forms the inner cavity. Continuous cooling and pulling maintain precise shape and dimensions. This method is widely used in producing water supply/drainage pipes, electrical conduit pipes, and industrial piping.

The pipe extrusion system continuously produces plastic pipes with stable shapes and dimensions

Coating extrusion

Coating extrusion is the process of applying molten plastic directly onto a substrate such as paper, fabric, or aluminum foil. The substrate is passed through the extrusion die, where the molten plastic adheres under high pressure and temperature. This method is commonly applied in the production of insulated cables, moisture-resistant packaging, and functional coatings for textiles

Coating extrusion is a technique applied in the production of plastic-coated cables

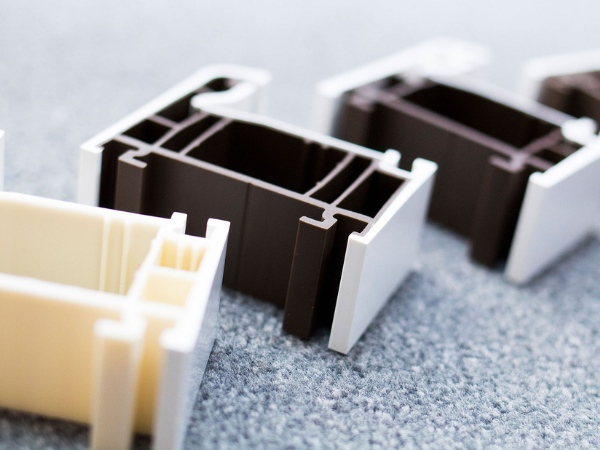

Co-extrusion

Co-extrusion uses two or more extruders simultaneously to feed different plastic streams into a common die, producing multilayer products. The layers may vary in color, mechanical properties, or functions. The relative thickness of each layer is controlled by the design and speed of each extruder. Co-extrusion can be applied to films, sheets, pipes, and profiles.

Co-extrusion technology enables the production of multilayer plastic products

Lamination/Multilayer extrusion

This technique coats one or more layers of plastic onto a substrate to enhance mechanical strength, environmental resistance, or barrier properties. In some cases, the plastic layer also serves as an adhesive between two materials. Typical applications include polyethylene-coated paper packaging, composite laminated films, and insulating layers for electronic devices

Lamination extrusion is a technique of coating one or more layers of plastic onto a substrate

Optimizing extrusion efficiency with PVC Compound

In the field of plastic manufacturing and processing, PVC Compound is one of the most widely used materials due to its ability to improve processing efficiency and product quality. APEX’s PVC Compound is a pre-mixed formulation of polyvinyl chloride (PVC) resin and specialized additives, optimized for applications such as electrical cables, building materials, plastic pipes, and various technical products.With its chemical stability, excellent molding properties, and high weather resistance, PVC Compound offers significant benefits such as:

- Cost optimization: PVC Compound reduces the use of virgin resin by partially replacing raw materials while still ensuring product quality. It also enhances extrusion productivity thanks to its good flow and easy processing, while minimizing equipment wear - helping reduce maintenance costs and extend machine lifespan.

- Improved product quality: Using PVC Compound in extrusion enhances rigidity, strength, and dimensional stability of plastic products. It also reduces shrinkage during cooling while improving surface smoothness and uniformity.

- Environmental friendliness: PVC Compound helps reduce dependence on virgin plastics, conserving natural resources. Moreover, many formulations are recyclable, supporting green manufacturing and sustainable development in the modern plastics industry.

Optimizing plastic extrusion efficiency with PVC Compound

From traditional technologies such as blown film and pipe extrusion to advanced solutions like multilayer or functional coating extrusion, extrusion technology continues to play a foundational role in plastic processing. To maximize production efficiency and product quality, selecting the right material is a key factor. Contact VNapex today for detailed consultation on PVC Compound - the solution to help optimize costs, boost productivity, and enhance the quality of your extrusion products!