- Home

- Blog

- Plastic Polymer Composite Article

- What is filler masterbatch resin? How is it applied?

What is filler masterbatch resin? How is it applied?

What is Filler Masterbatch?

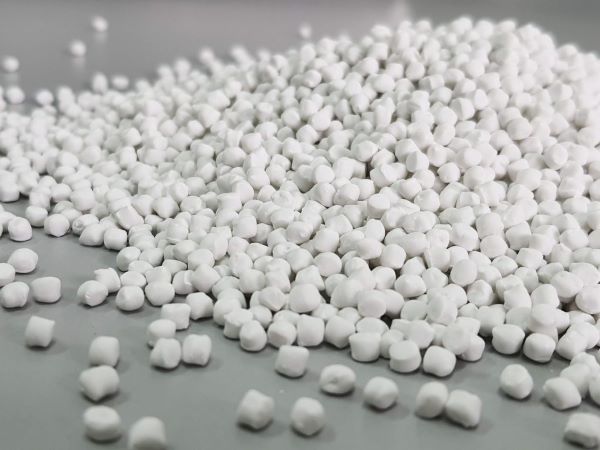

Filler masterbatch (also called plastic filler) is an additive made from a mix of calcium carbonate powder (CaCO₃), base plastic resin, and special additives.It is commonly used in the plastic industry to improve product strength, reduce production costs, and increase working efficiency during the manufacturing process.

Filler masterbatch helps reduce costs, increase efficiency, and improve product quality.

- Step 1: Mix calcium carbonate powder, base resin, and plastic additives evenly using a high-speed mixer to ensure consistency.

- Step 2: Heat the mixture to an appropriate temperature until all components are completely melted.

- Step 3: Cool the melted mixture, then feed it into a twin-screw extruder to compress and push it toward the shaping mold.

- Step 4: The shaped mixture passes through a cutting system to form small, uniform plastic pellets — the final filler masterbatch used in the plastics industry.

What Are the Functions of Filler Masterbatch?

-

Optimize Production Costs:The main component of filler masterbatch is calcium carbonate CaCO₃, a plentiful and low-cost raw material with stable quality.By using this material, manufacturers can reduce the amount of virgin resin required, thereby lowering production costs and improving price competitiveness.

-

Improve Mechanical Properties:Filler masterbatch helps increase hardness, enhance flexibility, and reduce shrinkage rates.As a result, it improves the overall quality of the final product, ensuring durability and dimensional stability for plastic items.

- Flexible application: Thanks to its stable chemical properties and high compatibility with various base plastics, filler masterbatch can be processed in the form of granules or ground into powder. This makes it easy to adjust formulations to meet different technical requirements.

- Increase Processing Stability:Filler masterbatch helps spread heat evenly during film blowing and fiber drawing.This reduces air bubbles and surface defects, making plastic products smoother and more attractive.

Applications of Filler Masterbatch in Production

Below are the applications of filler masterbatch in production:

The applications of filler masterbatch in production

Injection Molding

Injection molding is a modern manufacturing method that works through two main stages: the plastic is melted and injected into a mold under high pressure, then shaped into the final product.This technology is especially effective for producing thin plastic items such as buckets, basins, baskets, containers, toothbrushes, and small plastic parts like toys.

Benefits of Using Filler Masterbatch in Injection Molding:-

Shorten Production Cycle Time:Thanks to the good thermal conductivity of CaCO₃, filler masterbatch helps speed up the mold cooling process, thereby reducing the time required for each production cycle.

- Save Material Costs: CaCO₃, the main component of filler masterbatch, is much cheaper than virgin resin, helping significantly reduce production material costs.

- Reduce Energy Consumption:A shorter production cycle means less electricity is used for each product.

- Improve Molding Stability:Filler masterbatch helps make the molding process more stable, allowing products to have accurate shapes with fewer defects.

- Reduce Carbon Emissions:By replacing part of the virgin resin with CaCO₃, filler masterbatch helps lower carbon emissions and contributes to environmental protection.

- Improve Mechanical Strength:The products become more resistant to impact and bending, resulting in better overall durability.

- Increase Tear Resistance:Even when the product thickness is reduced, it still maintains good mechanical strength.

- Improve Printing Efficiency:Products made with filler masterbatch have better ink adhesion, resulting in higher print quality for labels and packaging.

Extrusion

Extrusion is one of the most common plastic manufacturing methods today. In this process, mixed materials are put into the feeder of the extruder. Inside the machine, the mixture is melted at a high temperature and then pushed through a mold to form long plastic strands. The shape of the strands depends on the design of the mold, usually round or square.After leaving the mold, the plastic strands are cooled by air or water on a conveyor belt so they can harden. Then, a cutting system trims them into equal pieces for packing and later use.

This method is popular because the machines are simple and easy to operate. However, it is mainly used for products without complex designs, such as PVC pipes, straws, or rain gutters.

The use of filler masterbatch in extrusion

- Reduce production costs: By replacing part of the virgin plastic with calcium carbonate CaCO₃ the main component of filler masterbatch manufacturers can lower raw material costs, thereby increasing their competitiveness in the market.

- Improve mechanical properties: Filler masterbatch enhances the hardness and strength of the final product, ensuring stable quality during use.

Blow molding

Blow molding is one of the most common methods in the plastic packaging industry. It is widely used to make different kinds of films such as heavy-duty packaging film, ultra-thin film, biodegradable film, paper-coated film, film rolls, shopping bags, and garbage bags.The process starts by feeding the mixed materials into the hopper, then moving them to the screw extruder where they are melted at a high temperature. The melted plastic is sent to the die head, where air is blown in to form a film bubble and cooled immediately. Finally, the film passes through the rollers and is wound into rolls by the take-up system.

Applications of filler masterbatch in blow film technology:

- Increase stiffness and thermal stability: Filler masterbatch helps the film maintain its shape better and reduces shrinkage when exposed to high temperatures.

- Increase the opacity of the product:It provides a more uniform and professional appearance, suitable for packaging that requires good coverage.

- Optimize costs: Calcium carbonate CaCO₃, the main component of filler masterbatch, is less expensive than virgin plastic, helping save raw materials and reduce overall production costs.

VN APEX Filler Masterbatch

VNapex Filler Masterbatch is a high-quality product made from carefully selected calcium carbonate CaCO₃ powder, combined with virgin plastic resin and special additives. With strict quality control and advanced production technology, VNapex products not only help reduce production costs, improve hardness, and enhance thermal stability, but also increase processability and printing performance on plastic surfaces.VNapex filler masterbatch is now widely used in various manufacturing processes such as injection molding, extrusion, blow film, and fiber drawing. It is trusted by many domestic and international manufacturers thanks to its consistent quality, cost efficiency, and ability to be customized according to technical requirements.

The use of filler masterbatch in plastic production not only optimizes manufacturing costs but also significantly improves product quality. From injection molding and extrusion to blow film, filler masterbatch plays an increasingly important role in modern production. Understanding what filler masterbatch is helps businesses choose the right material, enhance production efficiency, and strengthen competitiveness in the market.

Article Classification

Recent Articles

- What is limestone powder? Applications of limestone powder

- What is filler masterbatch resin? How is it applied?

- Top 10 types of plastics used in injection molding technology

- What are fillers? Classification and applications of plastic fillers

- What are plastic additives? 11+ common types of plastic additives