- Home

- News

- Products Information

- What is Composite Plastic? Characteristics and Practical Applications

What is Composite Plastic? Characteristics and Practical Applications

What is composite plastic? Exploring its practical applications

What is composite plastic?

In materials engineering, the term composite refers to synthetic materials created by combining different substances. The purpose of this combination is to enhance properties such as strength, durability, and performance compared to each material on its own.So, what is composite plastic? It is a high-performance engineered plastic made from two or more distinct phases of material. Typically, it includes a matrix phase, often unsaturated resins like polyester or epoxy, and a reinforcement phase, such as fiberglass, stone powder, or other technical fillers.

Composite plastic is also widely known as FRP (Fiberglass Reinforced Plastic). Thanks to its superior properties, this material is now extensively applied in industries including construction, transportation, chemical processing, marine engineering, and household equipment.

Structure of composite plastic

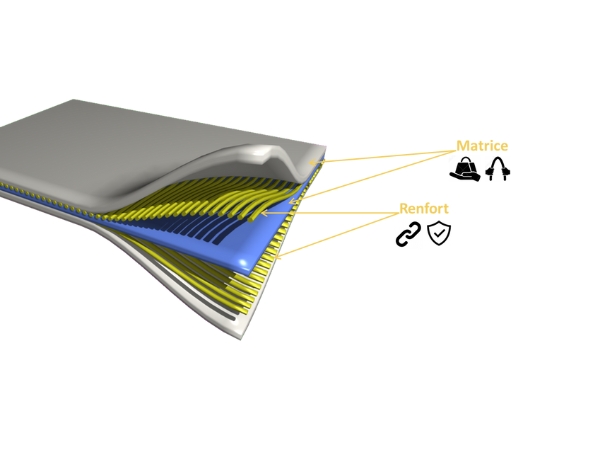

To fully understand what is composite plastic, it is important to look at its structure. Composite plastic is made up of two main components: the matrix phase and the reinforcement phase. Each plays a critical role in shaping the overall properties of the material.- Matrix phase: This is the primary component that binds the reinforcement elements together, forming a solid and durable whole. The matrix is typically made from polymers such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), epoxy resin, rubber, or ceramics. It is also known as the continuous phase because it surrounds and holds the fibers or particles in place.

- Reinforcement phase: This part significantly improves the mechanical properties of the composite, such as tensile strength, stiffness, and load-bearing capacity. Reinforcements may come in the form of short or long fibers - commonly fiberglass, carbon fiber, acrylic fiber, or cellulose fiber - or in particulate form such as wood powder, stone powder, or metal particles.

Composite plastic is made up of a matrix phase and a reinforcement phase

What are the advantages of composite plastic?

What are the advantages of composite plastic? Composite plastic delivers outstanding performance and can effectively replace many traditional materials such as metal or wood. Beyond that, it also offers several remarkable benefits:High strength

Composite plastic is 2 -3 times stronger than wood or metal under the same conditions. Thanks to the combination of the matrix and reinforcement phases, it provides excellent stiffness and can withstand bending, tensile stress, and strong impacts. This makes it especially suitable for products frequently exposed to force, such as outdoor trash bins, water treatment columns, or public facilities.Lightweight and easy to install

Compared to metals, composite plastic is significantly lighter, which reduces construction loads and improves efficiency in handling and transportation. Because of its light weight yet high strength, it is also widely used in the aerospace industry to manufacture aircraft components.Excellent chemical resistance and corrosion protection

One of the key advantages of composite plastic is its ability to resist corrosion caused by environmental factors and various chemicals, without the need for protective coatings. Moreover, it has impressive heat resistance: around 200 - 300°C with organic matrices, over 600°C with metallic matrices, and up to 1,000°C with ceramic-based composites.Easy to mold

Another important advantage of what is composite plastic lies in its ease of molding. With high formability, composite plastic allows for the production of items in a wide range of shapes and sizes. This makes it suitable for both aesthetic and technical requirements in various fields, from household use to industrial applications.

With good formability, composite plastic enables diverse product designs

- Open mold technology: Includes common methods such as spray-up, hand lay-up, or machine-assisted lay-up. This is a simple technique, often used for large-sized products or small-scale production.

- Diaphragm molding: Uses molds capable of applying pressure, such as elastic diaphragm molds, vacuum bag molding, or a combination of vacuum and autoclave processes.

- Resin infusion: Resin is infused into the reinforcement fibers under vacuum pressure or in normal conditions. This ensures even resin distribution and stronger bonding between material layers.

- Compression molding: Covers techniques like direct molding, hot pressing, and precision molding. It is suitable for mass production of complex-shaped parts requiring high dimensional accuracy.

- Filament winding: With the help of automated machinery, fibers are wound according to a pre-set design, creating a strong and durable structure. This method is commonly used for producing pipes, storage tanks, and cylindrical components.

- Pultrusion: A fully automated and continuous process that produces highly uniform composite products. The resulting materials have excellent load-bearing capacity, making them an ideal replacement for traditional materials such as metal or wood.

Applications of composite plastic

What are the applications of composite plastic? Thanks to its superior properties, composite plastic is now widely used in various aspects of daily life and across multiple industrial sectors, such as:Construction industry

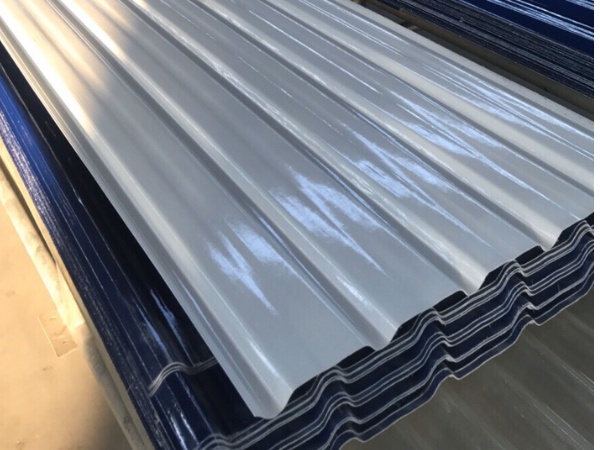

Composite plastic is commonly used to manufacture water tanks, roofing sheets, wall panels, flooring, railings, composite doors, and structural components in special environments such as coastal areas or chemical plants. With its long service life, it helps reduce maintenance and operating costs in both residential and industrial projects.Transportation

In the transportation sector, composite plastic plays an important role in reducing vehicle weight, thereby saving fuel and improving operational efficiency. It is applied in the production of car bodies, bus panels, train components, ship hulls, rescue boats, kayaks, as well as parts for motorcycles and sports bicycles.

Composite plastic is used to manufacture car bodies

Chemical industry

Composite plastic is an ideal choice for chemical plants, production systems, and treatment facilities thanks to its strong corrosion resistance. It is widely used in the manufacturing of chemical storage tanks, acid/alkali pipelines, wastewater treatment systems, exhaust fans, tank covers, and other equipment that require frequent contact with chemicals.Aerospace

In aerospace engineering, composite is used to produce aircraft wings, fuselage panels, passenger seats, cabin partitions, helicopter blades, and even certain spacecraft and satellite components. Its lightweight nature helps reduce fuel consumption, while its high mechanical strength ensures absolute safety at high speeds and under extreme conditions.Renewable energy

In the renewable energy sector, composite plastic contributes to the efficiency and durability of equipment. A typical example is wind turbine blades, which are usually very large but must remain lightweight while withstanding strong winds - making composites the primary material of choice. Additionally, this material is used for support frames and protective casings in solar panel systems designed to operate outdoors for extended periods

Composite plastic is used as protective casings for wind energy systems

Household and furniture

Composite is also widely applied in household products thanks to its modern appearance, easy moldability, and high durability. Typical examples include flower pots, bathtubs, washbasins, countertops, decorative shelves, and outdoor furniture. These products made from composite last longer, are easy to clean, and withstand different weather conditions.Sports and recreation

In the sports industry, composite is an ideal material for equipment requiring flexibility, light weight, and high strength. Products such as tennis rackets, badminton rackets, golf clubs, sports bicycles, fishing rods, helmets, skis, and surfboards all make use of composite to enhance performance and deliver the best user experience.Medical and advanced engineering

Composite plastic is also present in modern medical equipment, where materials need to be lightweight, durable, and easy to sanitize. It is used to produce prosthetics, orthopedic braces, hospital beds, stretchers, and casings for medical devices. In advanced engineering, composites are employed in precision components that must withstand high loads, serving as an effective alternative to metal in many applications.Electrical and electronics

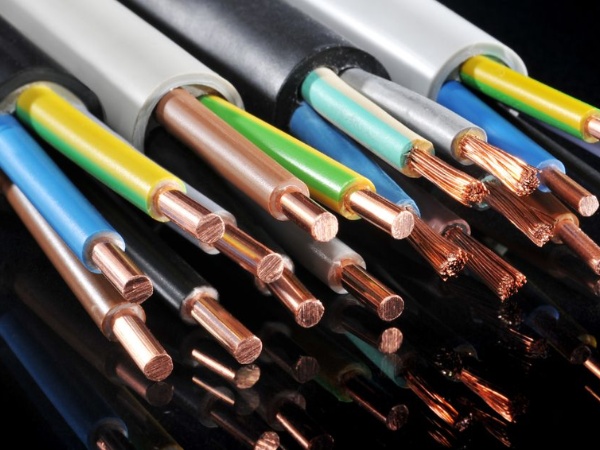

Thanks to its excellent insulating properties and weather resistance, composite plastic is applied in the production of outdoor electrical cabinets, switchboards, insulating casings, high-voltage insulators, UPS housings, and more. The material ensures electrical safety while resisting melting, cracking, or degradation under tropical or humid conditions

Composite plastic is used in the production of wire insulation materials