NEWS & EVENTS

- Home

- News

- Products Information

- What is VC CV CVV Electrical Wire?

What is VC CV CVV Electrical Wire?

August 13,2025

In today’s power transmission and distribution systems, VC, CV, and CVV wires are among the most common types of electrical cables, widely applied in both residential and industrial settings. But exactly, what is VC CV CVV electrical wire, and how do these types differ in terms of structure, function, and production materials? This article will help you understand each type of wire, the role of the insulation layer, and the application of PVC Compound in the manufacturing process.

What is VC CV CVV electrical wire?

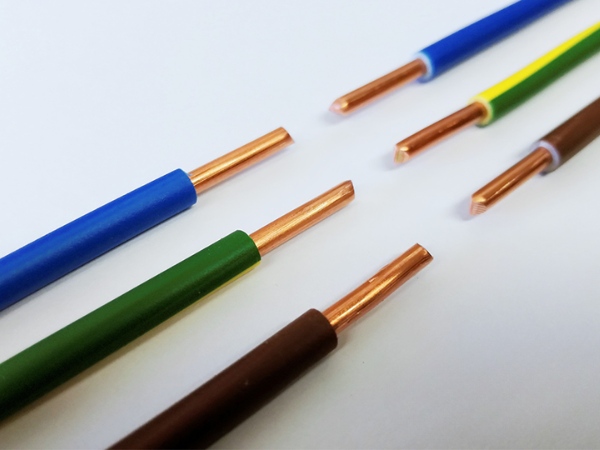

VC wire is a solid single-core conductor with good electrical conductivity

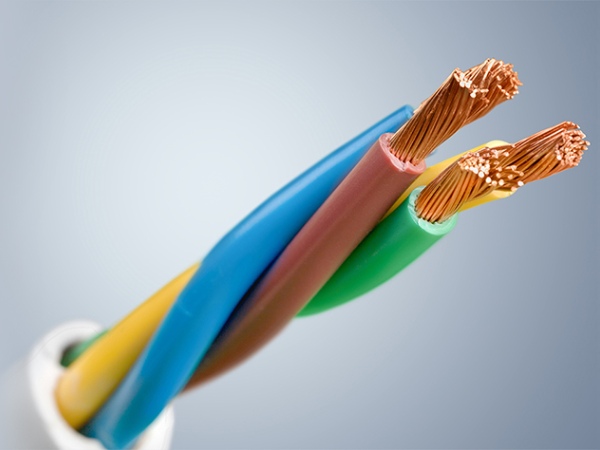

CV wire is suitable for fixed electrical installations

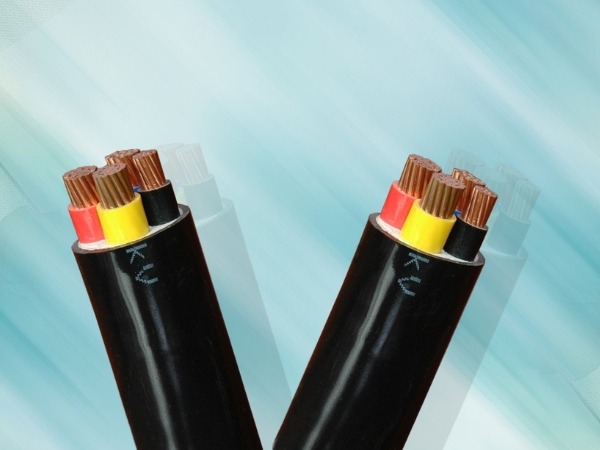

CVV is a low-voltage power cable with copper conductors

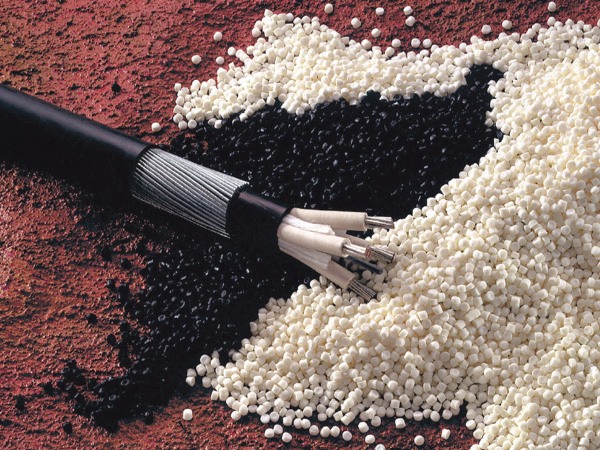

PVC compound granules specialized for electrical wire and cable production

PVC Compound for the insulation layer of electrical wires

PVC compound is used as the filler layer between conductors in electrical cables

Specialized PVC compound used for the outer sheath of electrical cables

Key advantages of VNapex PVC Compound:

What is VC CV CVV electrical wire?

What is VC CV CVV electrical wire?

What is VC CV CVV electrical wire? In residential and industrial electrical systems, VC, CV, and CVV wires are among the most commonly used types of cables, each designed for specific applications and installation environments. Below are the technical characteristics of each type:VC Wire

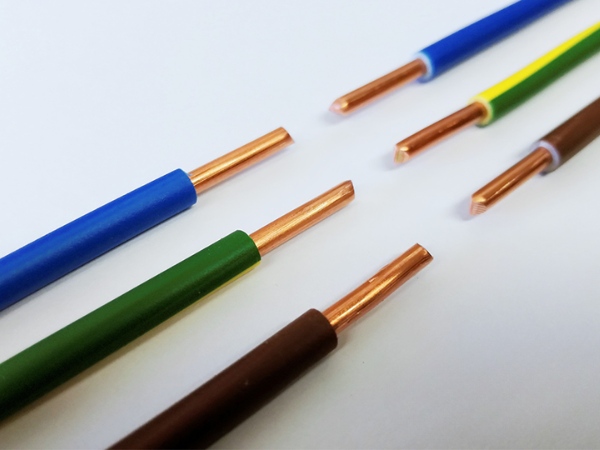

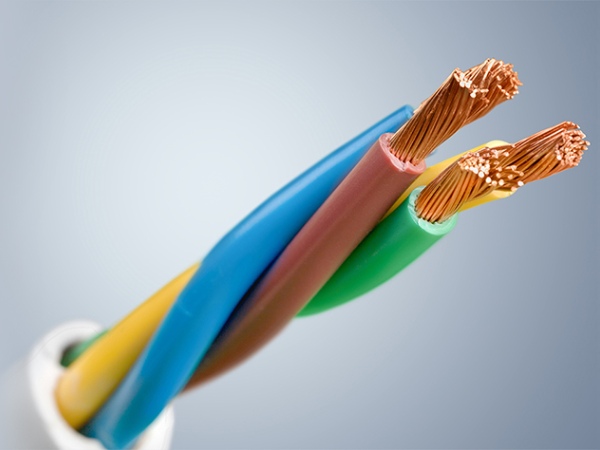

VC wire is a solid single-core conductor, made from high-purity copper or aluminum, insulated with PVC or XLPE.- Conductor: Refined copper or aluminum with excellent conductivity.

- Rated voltage: 0.6/1kV.

- Technical standard: Complies with QCVN 04:2009 issued by the Ministry of Science and Technology.

- Applications: VC wire is often used for signal transmission between receiving and transmitting devices such as radios, televisions, and similar applications.

VC wire is a solid single-core conductor with good electrical conductivity

CV Wire

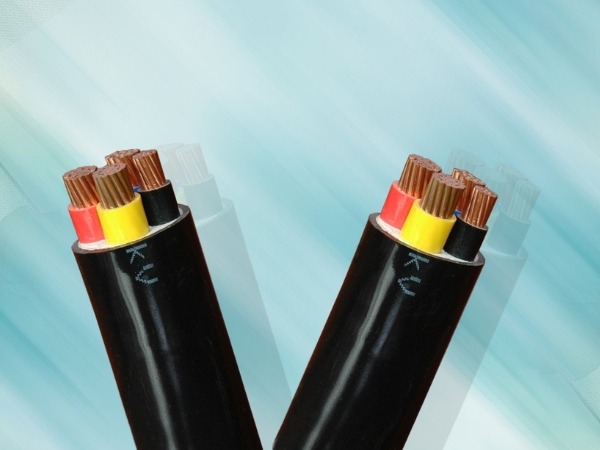

What is VC CV CVV electrical wire? CV wire is a single-core cable with a copper conductor, insulated with PE or PVC, suitable for fixed electrical systems.- Conductor: 7 or 19 concentric copper strands.

- Rated voltage: 0.6/1kV.

- Operating temperature: 70°C (continuous).

- Technical standard: QCVN 04:2009/BKHCN.

- Applications: Widely used in environments such as open spaces, conduits, technical trenches, cable trays, or even buried directly underground.

CV wire is suitable for fixed electrical installations

CVV Wire

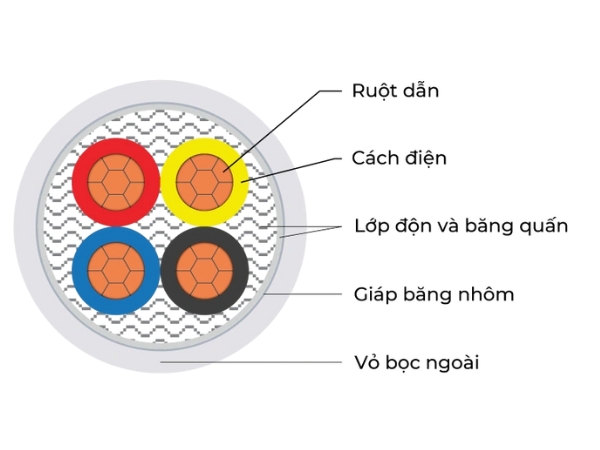

CVV is a low-voltage power cable with copper conductors, usually 1 to 4 cores, insulated with PVC, and protected by a black PVC outer sheath with core identification markings.- Conductor: Copper.

- Number of cores: 1 - 4.

- Rated voltage: 0.6/1kV, operating frequency 50Hz.

- Operating temperature:

- Continuous: 70°C.

- Short circuit (maximum 5 seconds): ≤ 300mm²: 160°C; ≥ 300mm²: 140°C.

- Technical standard: IEC 60502-1 (600/1000V).

- Applications: Suitable for power transmission and distribution systems in both industrial and residential projects.

CVV is a low-voltage power cable with copper conductors

So, what is VC CV CVV electrical wire in summary? These are all low-voltage power cables widely used in both residential and industrial electrical systems. Their main differences lie in the protective sheath structure, which determines how well each type adapts to specific environmental conditions and how durable it is over time.

To meet increasingly high requirements for quality and safety, specialized PVC compounds for wire and cable manufacturing have been developed with improved formulations. These compounds not only ensure stable insulating performance but are also environmentally friendly - free of heavy metals and compliant with RoHS and REACH standards.

The role of the insulation layer in VC, CV, and CVV electrical wires

What is the role of the insulation layer in VC CV CVV electrical wires? The insulation layer is an essential part of the structure of electrical wires and cables, playing a key role in ensuring safety, durability, and the efficient operation of the entire electrical system.- Prevent electrical faults: Minimizes short circuits and grounding issues that can damage equipment and disrupt the system.

- Reduce fire and explosion risks: Prevents electrical discharge or direct contact between conductors, especially in flammable environments.

- Optimize transmission efficiency: Keeps current flowing in the right direction, reduces power loss, and improves overall performance.

- Protect conductors from the environment: Shields against moisture, chemicals, temperature changes, and external impacts, extending the cable’s lifespan.

- Ensure user safety: Prevents current leakage, lowering the risk of electric shock when accidental contact occurs.

What materials are used for the insulation layer of electrical wires?

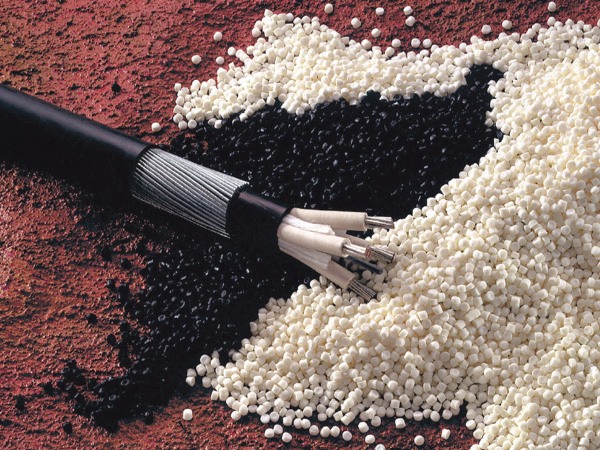

The insulation layer is typically made from PVC, rubber (natural or synthetic), or XLPE (cross-linked polyethylene). Among these, PVC (Polyvinyl Chloride) is the most common choice for low-voltage applications thanks to its ease of processing, flexibility, good insulation properties, and affordable cost.To meet increasingly high requirements for quality and safety, specialized PVC compounds for wire and cable manufacturing have been developed with improved formulations. These compounds not only ensure stable insulating performance but are also environmentally friendly - free of heavy metals and compliant with RoHS and REACH standards.

PVC compound granules specialized for electrical wire and cable production

Depending on the intended application, PVC compound can be flexibly customized in terms of hardness, color, heat resistance, cold resistance, or weather resistance. This makes it an optimal solution for electrical wire manufacturers looking to enhance the durability and reliability of their products under various environmental conditions.

Application of PVC Compound in electrical wire manufacturing

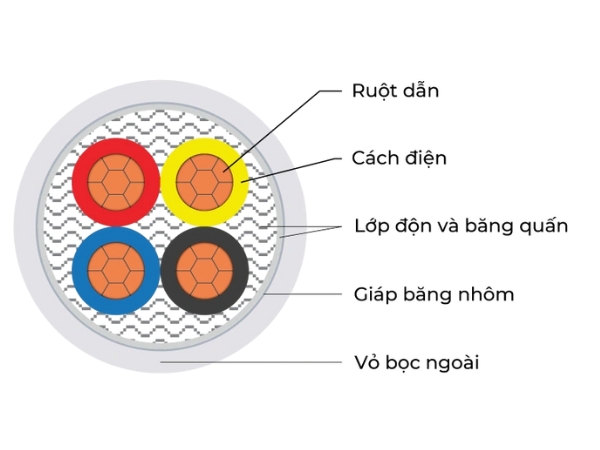

What is the application of PVC Compound in the production of VC CV CVV electrical wires? In the field of wire and cable manufacturing, PVC Compound is formulated with specialized recipes to ensure the mechanical, electrical, and environmental properties required for each component of the cable, as follows:PVC Compound for the insulation layer of electrical wires

The insulation layer is an essential part of wire and cable construction, preventing direct contact between conductors or between conductors and other conductive materials, thereby reducing the risk of short circuits. PVC Compound is widely used for insulation thanks to its excellent dielectric properties, high voltage resistance, and effective prevention of current leakage, ensuring safety during power transmission.

PVC Compound for the insulation layer of electrical wires

PVC Compound for the filler layer in electrical cables

The filler layer is placed between conductors or between the conductor and the sheath to enhance mechanical strength while maintaining the geometric stability of the cable. Using PVC Compound for the filler improves mechanical durability, moisture resistance, and provides additional insulation, thereby extending the service life of the product under harsh working conditions.

PVC compound is used as the filler layer between conductors in electrical cables

PVC Compound for the outer sheath of electrical cables

The outer sheath is the final protective layer, covering the entire cable structure and shielding it from mechanical stress, UV radiation, chemicals, and adverse environmental conditions. PVC Compound is a preferred material for sheathing due to its flame-retardant properties, corrosion resistance, and flexibility, making it suitable for a wide range of installations—from heavy industry to residential electrical systems

Specialized PVC compound used for the outer sheath of electrical cables

Where to buy high-quality PVC Compounds?

If you are looking for a stable supply of high-performance PVC compound pellets that meet current technical standards, VNapex is a trusted partner. VNapex specializes in researching and developing customized formulations for specific applications such as deep-freeze resistance, UV protection, or harsh weather durability.Key advantages of VNapex PVC Compound:

- Eco-friendly: The formulation is free of lead, chromium, and other heavy metals, complying with safety and environmental protection standards.

- Wide operating temperature range: Available in grades suitable for temperatures from 60°C to 105°C, ideal for both insulation layers and cable sheathing.

- Flexible customization: Customers can request adjustments in plasticizers, colors, and hardness to match their technical design requirements.

- Cost optimization: Competitive pricing makes it suitable for both large-scale manufacturing and specialized engineering projects.